In the construction and industrial sectors, rolling shutter doors are highly favored for their durability, security, and space - saving features. From commercial storefronts to industrial warehouses, these doors provide reliable protection against the elements, unauthorized access, and potential hazards. At the heart of the rolling shutter door production process lies the rolling shutter door forming machine, a sophisticated piece of equipment that transforms flat metal sheets into functional an

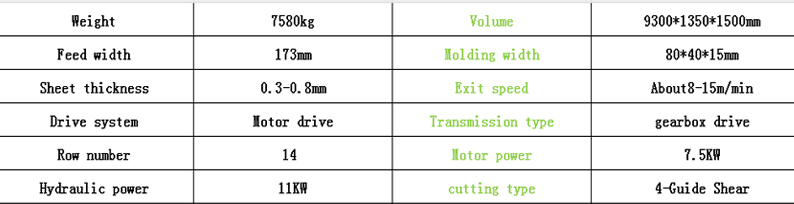

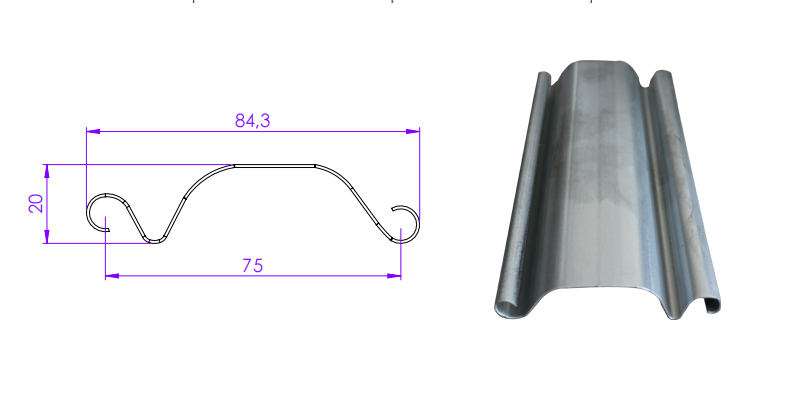

The fundamental working principle of a rolling shutter door forming machine is based on the concept of roll - forming. This process involves passing a continuous strip of metal, typically steel or aluminum coils, through a series of precisely designed rollers. As the metal strip moves through the rollers, it is gradually bent and shaped into the desired profile of the rolling shutter door slats or panels.

The process commences with the uncoiling of the metal coil. The coil is loaded onto an uncoiler, which feeds the metal strip at a controlled speed into the roll - forming section of the machine. The uncoiler is equipped with mechanisms to maintain consistent tension on the metal strip, ensuring a smooth and even feed. Once inside the roll - forming section, the metal strip encounters a sequence of roller sets. Each set of rollers is designed to make a specific bend or contour to the metal, gradually transforming it into the final shape. The rollers are carefully positioned and adjusted to achieve the required dimensions and shape accuracy of the rolling shutter door components.

After the roll - forming process, the formed metal slats or panels are cut to the desired length. This is typically done using a cutting mechanism, such as a shear or a high - precision saw. The cutting operation is precisely controlled to ensure that each piece is of the correct length, allowing for seamless assembly of the rolling shutter door. Some advanced rolling shutter door forming machines may also incorporate additional processes, such as punching holes for rivets or installing locking mechanisms, during the production cycle.

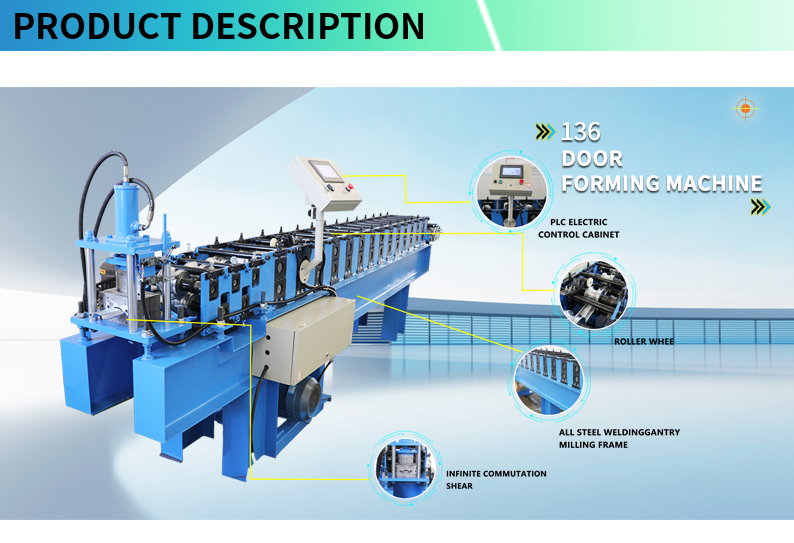

Components of a Rolling Shutter Door Forming Machine

Components of a Rolling Shutter Door Forming Machine

The uncoiling system is the starting point of the production process. It consists of a sturdy frame that supports the metal coil and a mechanism for unwinding it. Modern uncoilers often feature adjustable tension control, which is crucial for maintaining a steady and consistent feed of the metal strip. This tension control prevents the strip from wrinkling, stretching, or becoming slack during the uncoiling process. Some high - end uncoilers are also equipped with automatic coil loading systems, which can quickly and efficiently change coils, reducing downtime and increasing production efficiency. For example, in a large - scale manufacturing facility, an automatic coil - loading uncoiler can significantly enhance productivity by minimizing the time spent on manual coil changes.

The roll - forming section is the core component of the rolling shutter door forming machine. It comprises a series of roller stands, each housing a set of rollers. These rollers are typically made of high - quality materials, such as hardened steel, to withstand the forces exerted during the roll - forming process. The rollers are precisely machined and polished to ensure a smooth surface finish on the formed metal parts. The design of the rollers is highly specific to the profile of the rolling shutter door being produced. For instance, if the door requires a particular slat shape with specific bends and contours, the rollers will be engineered accordingly. The roller stands are arranged in a sequential manner, with each set of rollers making incremental bends to the metal strip until the desired shape is achieved. Some advanced roll - forming sections may also incorporate adjustable roller positions, allowing for quick and easy changeovers between different door profiles.

The cutting mechanism is responsible for trimming the formed metal slats or panels to the required length. There are two main types of cutting mechanisms commonly used in rolling shutter door forming machines: mechanical shears and hydraulic cutters. Mechanical shears operate by using a set of blades that are driven by a mechanical linkage to cut through the metal. They are relatively simple in design and are suitable for cutting thinner metal sheets. Hydraulic cutters, on the other hand, utilize hydraulic pressure to power the cutting blades. They are capable of making cleaner and more precise cuts, especially when working with thicker metal materials. Some high - tech cutting mechanisms are computer - controlled, enabling accurate length cuts and the ability to program different cutting lengths for batch production. This ensures consistency in the length of the door components, facilitating easier assembly and installation.

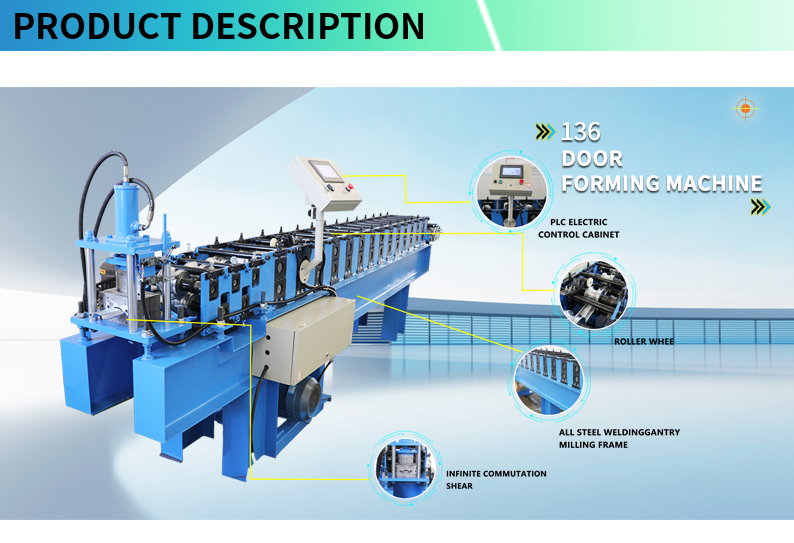

The control system of a rolling shutter door forming machine is what enables the operator to manage and monitor the entire production process. It can range from a basic manual control panel to a sophisticated computer - numerical - control (CNC) system. A basic control panel usually consists of switches, buttons, and dials for controlling functions such as the speed of the machine, the operation of the uncoiler, and the activation of the cutting mechanism. In contrast, a CNC system offers advanced features such as precise parameter setting, real - time monitoring of the production process, and the ability to store and recall different production programs. With a CNC control system, operators can input specific details about the rolling shutter door, such as the slat profile, length, and quantity, and the machine will automatically adjust the roll - forming and cutting processes accordingly. This not only improves the accuracy and efficiency of production but also reduces the likelihood of human error.

Guiding and support structures play a vital role in ensuring the stability and alignment of the metal strip during the production process. These structures include guide rails, supports, and alignment devices that keep the metal strip in the correct position as it passes through the uncoiling system, roll - forming section, and cutting mechanism. Properly designed guiding and support structures prevent the metal strip from deviating from its intended path, which could result in uneven or defective products. They also help to distribute the forces exerted on the metal strip evenly, reducing the risk of deformation or damage to the material. For example, guide rails are used to keep the metal strip centered as it enters the roll - forming section, ensuring that the rollers can shape it accurately.

Manual rolling shutter door forming machines are the most basic type of equipment. They require significant human intervention in the operation process. Operators need to manually control functions such as the uncoiling of the metal coil, adjusting the roller positions, and activating the cutting mechanism. These machines are typically smaller in size and have a lower production capacity compared to their automated counterparts. They are often used in small - scale workshops or for producing custom - made rolling shutter doors in limited quantities. While manual machines may be less expensive to purchase, they are more labor - intensive and have a slower production speed. However, they offer a high degree of flexibility for producing unique or specialized door designs that may not be feasible with automated machines.

Semi - automatic rolling shutter door forming machines incorporate some level of automation to improve production efficiency. They usually feature automated uncoiling systems and may have partially automated roll - forming and cutting processes. For example, the uncoiling of the metal coil may be automatically controlled, while the operator still needs to manually adjust the roller positions for different door profiles and initiate the cutting process. Semi - automatic machines strike a balance between cost and productivity, making them a popular choice for medium - sized manufacturing operations. They can produce a relatively large number of rolling shutter doors in a given time frame while still allowing for some customization and manual adjustment when required.

Fully automatic rolling shutter door forming machines represent the pinnacle of technology in this field. These machines are equipped with advanced automation systems, including CNC control, automatic coil loading, and fully automated roll - forming and cutting processes. Once the production parameters are input into the control system, the machine can operate continuously without the need for constant manual supervision. They are capable of producing high - quality rolling shutter doors at a rapid pace, making them ideal for large - scale manufacturing facilities. Fully automatic machines can handle a wide variety of metal materials and door profiles, and they offer excellent precision and consistency in production. They also often come with built - in quality control features, such as sensors that detect any defects or irregularities in the formed parts, ensuring that only top - quality products are produced.

In commercial buildings, rolling shutter doors are commonly used for storefronts, shops, and service stations. They provide security when the premises are closed, protecting the interior from theft and vandalism. The aesthetic appeal of rolling shutter doors can also be enhanced with various finishes and designs, making them an attractive addition to the building's facade. Rolling shutter door forming machines are used to produce doors that are customized to fit the specific dimensions and design requirements of each commercial establishment. For example, a high - street shop may require a rolling shutter door with a unique color and pattern to match its branding, which can be easily achieved using a suitable forming machine.

Industrial facilities, such as factories, warehouses, and garages, rely on rolling shutter doors for their large - scale access and security needs. These doors need to be robust and durable to withstand heavy usage, harsh environmental conditions, and potential impacts. Rolling shutter door forming machines are used to produce heavy - duty doors with strong metal profiles and reliable locking mechanisms. In a warehouse, for instance, large rolling shutter doors are required to allow the easy movement of goods in and out using forklifts and other industrial vehicles. The forming machines ensure that the doors are manufactured to the exact specifications, providing a secure and functional access solution for the facility.

Although less common than in commercial and industrial settings, rolling shutter doors are also used in residential buildings, especially in areas where security and weather protection are a concern. They can be installed on garages, balconies, and windows to enhance the safety and energy efficiency of the home. Rolling shutter door forming machines can produce doors in a range of sizes and styles to suit different residential architectural designs. For example, in a coastal area, homeowners may opt for corrosion - resistant aluminum rolling shutter doors for their windows, which can be produced using specialized forming machines.

Public infrastructure projects, such as parking lots, subway stations, and utility shelters, also make use of rolling shutter doors. These doors need to meet specific safety and accessibility standards. Rolling shutter door forming machines are used to manufacture doors that comply with these requirements, ensuring the smooth operation and security of public facilities. For example, in a subway station, rolling shutter doors may be used to secure access to maintenance areas or to provide emergency exits. The forming machines can produce doors with the necessary features, such as fire - resistance and quick - release mechanisms, to meet the stringent safety regulations of public infrastructure.

plan and design the doors based on the overall building model, and then directly transfer the design specifications to the forming machine for production. Integration with BIM would reduce errors, improve communication between different stakeholders, and enhance the overall efficiency of construction projects. For example, if a change is made to the building design in the BIM model, the production parameters of the rolling shutter door forming machine can be automatically updated, ensuring that the doors are manufactured to the correct specifications.