Purlin roll forming machine is a specialized equipment used in the manufacturing of steel purlins, which are essential components in steel structure buildings. These machines are designed to efficiently roll and form flat steel coils into various shapes such as C, Z, and U, tailored to meet specific structural requirements.

Purlin Roll Forming Machine

Purlin roll forming machine is a specialized equipment used in the manufacturing of steel purlins, which are essential components in steel structure buildings. These machines are designed to efficiently roll and form flat steel coils into various shapes such as C, Z, and U, tailored to meet specific structural requirements.

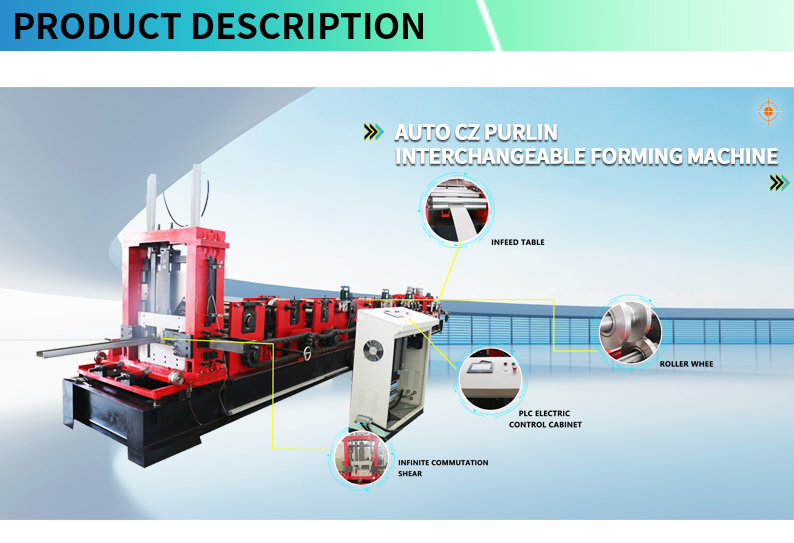

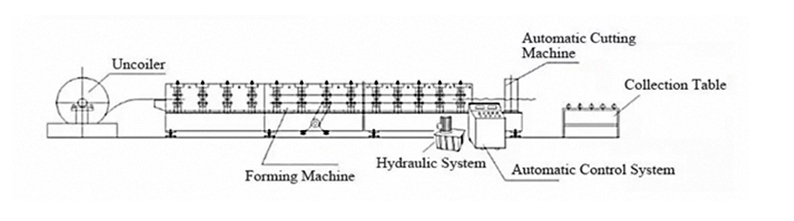

The working principle of a purlin roll forming machine involves feeding a steel coil into the machine, which then passes through a series of rollers. These rollers progressively bend and shape the steel into the desired purlin profile. Depending on the specific machine, it can produce C-purlins, Z-purlins, U-purlins, and other shapes. The machine is equipped with advanced control systems that ensure precision in the forming process, resulting in high-quality purlins.

In addition to the standard C, Z, and U shapes, there are specialized purlin roll forming machines such as the Angle Iron Purlin Forming Machine and the Omega Purlin Forming Machine. These machines are designed to produce purlins with unique shapes and profiles, catering to specific architectural and structural needs.

Fully Automatic C/Z Purlin Forming Machine is a high-end version that combines efficiency and automation. It is capable of producing both C-shaped and Z-shaped purlins with minimal manual intervention. This machine is equipped with advanced sensors and control systems that ensure precise and consistent forming, resulting in high-quality purlins.

Key features of purlin roll forming machines include:

High Efficiency: These machines are capable of producing purlins at a high speed, significantly increasing production capacity and reducing labor costs.

Versatility: They can be configured to produce purlins of different shapes and sizes, catering to the diverse needs of the construction industry.

Automation: Many modern purlin roll forming machines, especially the Fully Automatic C/Z Purlin Forming Machine, are equipped with automation features such as automatic feeding, cutting, and stacking, which further enhance productivity and reduce manual intervention.

Precision: The use of advanced control systems and precision rollers ensures that the produced purlins meet strict tolerances and specifications.

Durability: Made from high-quality materials, these machines are built to withstand the rigors of continuous production, ensuring long-term reliability and performance.

In the market, there are various manufacturers offering purlin roll forming machines, each with their unique selling points and technological advantages. Some manufacturers specialize in providing customized solutions, designing machines specifically to meet the unique needs of their customers.

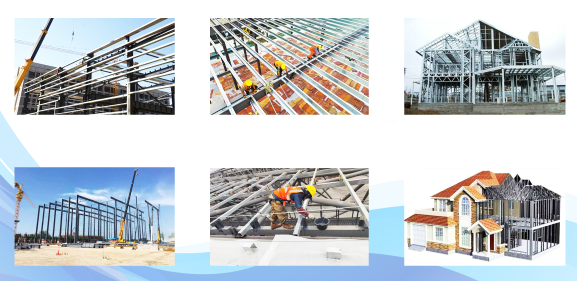

The demand for purlin roll forming machines is driven by the growing adoption of steel structures in the construction industry. Steel structures are known for their strength, durability, and resistance to natural disasters, making them a preferred choice for commercial and industrial buildings.

When selecting a purlin roll forming machine, it is important to consider factors such as machine capacity, precision, automation level, and after-sales support. Additionally, the manufacturer's reputation, experience, and track record in delivering high-quality machines should also be taken into account.

In conclusion, purlin roll forming machines, including C-Purlin Forming Machine, Z-Purlin Forming Machine, U-Purlin Forming Machine, Angle Iron Purlin Forming Machine, Omega Purlin Forming Machine, and Fully Automatic C/Z Purlin Forming Machine, play a crucial role in the efficient production of steel purlins for steel structure buildings. With their high efficiency, versatility, automation, precision, and durability, these machines are essential tools for manufacturers in the construction industry.

Working Principle

The operation of a Purlin Roll Forming Machine is a fascinating blend of mechanical engineering and precision. At its core, the machine works by passing a continuous strip of metal through a series of rollers and molds. These rollers are carefully calibrated to gradually bend and shape the metal according to the desired profile. For instance, when producing C - shaped purlins, the metal sheet is guided through a sequence of rollers that incrementally form the characteristic C - curve. The molds play a crucial role in ensuring that the final product meets the exact specifications in terms of dimensions and shape accuracy.

The process often involves a combination of cold - rolling techniques. Cold - rolling is preferred as it allows for better control over the material's properties, such as strength and surface finish. By working at room temperature, the metal retains its structural integrity while being shaped into the required form. Additionally, some advanced Purlin Roll Forming Machine are equipped with automated cutting mechanisms. Once the purlin has been formed to the appropriate length, these cutting devices swiftly and accurately sever the metal, ensuring a clean and precise cut.

Purlin Roll Forming Machine are engineered for high - volume production. Their automated nature allows for continuous operation, significantly reducing the time required to produce a large quantity of purlins compared to manual methods. For example, a modern, well - maintained machine can produce hundreds of linear meters of purlins in a single shift. This increased productivity not only saves time but also enables manufacturers to meet tight project deadlines more effectively.

One of the most significant advantages of using a Purlin Roll Forming Machine

is the consistency in product quality. Since the shaping process is machine - controlled, each purlin produced is virtually identical in terms of dimensions, shape, and structural integrity. This eliminates the variability that can occur with manual fabrication, resulting in a more reliable and uniform product. Construction projects benefit greatly from this as it ensures proper fit and function of the components during assembly.

In the long run, investing in a Purlin Roll Forming Machine can lead to substantial cost savings. The high production efficiency means that more units can be produced per unit of time, reducing the labor cost per product. Additionally, the consistent quality reduces the likelihood of product defects and waste, further cutting down on material costs. Moreover, as the machine can be adjusted to produce different profiles and sizes, it offers versatility, eliminating the need for multiple specialized tools or machinery for different projects.

Purlin Roll Forming Machine are highly adaptable and can be configured to produce a wide range of purlin profiles. Whether it's a standard C - purlin, Z - purlin, or a more complex and customized shape for a unique architectural design, these machines can be programmed or tooled accordingly. This flexibility allows construction companies and building material manufacturers to meet the diverse needs of their clients, expanding their market reach and competitiveness.

In the construction of industrial buildings, such as factories and warehouses, purlins are essential for providing structural support to the roof and walls. Purlin Roll Forming Machine enable the mass production of high - quality purlins that can withstand heavy loads and environmental stress. In residential construction, these machines are used to produce roofing tiles that not only offer protection from the elements but also enhance the aesthetic appeal of the house. For example, in modern housing developments, metal tiles produced by these machines are increasingly popular due to their durability and attractive appearance.

Building materials manufacturing plants rely on Purlin Roll Forming Machine to produce a variety of products for the construction market. These include pre - fabricated building components, where purlins and tiles are manufactured in a controlled factory environment and then transported to the construction site for assembly. This approach streamlines the construction process and improves overall project efficiency. Additionally, manufacturers can use these machines to produce specialized building materials for niche markets, such as eco - friendly or high - performance products.

The market for Purlin Roll Forming Machine is highly competitive, with manufacturers worldwide offering a diverse range of models to meet different customer requirements. In regions with booming construction industries, such as Asia and the Middle East, the demand for these machines is particularly high. Chinese manufacturers, for instance, have gained a significant share in the global market by offering cost - effective yet high - quality machines. These machines often come with advanced features, such as computer - controlled operation and quick - change tooling systems, to enhance productivity and flexibility.

In the European and North American markets, there is a growing demand for Purlin Roll Forming Machine that meet strict environmental and safety standards. Manufacturers in these regions focus on developing energy - efficient machines with advanced safety features to ensure operator well - being. As the construction industry continues to evolve, with an increasing emphasis on sustainable building practices and innovative designs, the Purlin Roll Forming Machine market is expected to witness further growth and technological advancements.

In conclusion, the Purlin Roll Forming Machine has revolutionized the construction and building materials industries. Its ability to produce high - quality, customized products efficiently has made it an essential tool for modern construction projects. As technology continues to advance, we can expect these machines to become even more sophisticated, further enhancing their performance and contribution to the built environment.