Gutter machines allow for a high degree of customization. Contractors can produce gutters in the exact lengths and widths required for a particular project. This is especially important in complex or unique architectural designs where standard pre - fabricated gutters may not fit. For instance, in a historic building with irregular rooflines, a gutter machine can be used to create gutters that conform precisely to the shape and dimensions of the roof, ensuring proper water drainage. Different ma

Gutter Machine

K - style gutters, also known as ogee or OG gutters, are the most popular type in residential construction. They feature a flat back, a flat bottom, and a decorative front. K - style gutter machines are widely available and can produce gutters in various widths, typically 5 inches and 6 inches being the most common. For example, the New Tech Machinery Mach II 5" and 6" gutter machines are well - known in the industry. The Mach II 5" gutter machine starts at $8,100 + USD depending on the configuration, and the Mach II 6" gutter machine starts at $9,500 + USD. These machines are equipped with polyurethane drive rollers, stainless - steel forming rollers, and an electric motor (3/4 hp, 110 vac, 60 hz, 1 ph, 11 amps). They can produce gutters at a speed of approximately 50 ft./min (15 m/min) and can handle materials such as painted steel (30 ga. to 24 ga.), painted aluminum (.019" to.032"), and copper (16 oz. to 20 oz., 3/4 hard).

Half - round gutters have a classic and elegant appearance. They are often used in historical restorations or on homes with a more traditional architectural style. Half - round gutter machines can produce gutters in sizes such as 6", 7", and 8". Some machines offer additional features like Euro Curl or Reverse Curl profiles. For instance, Gutter Machinery offers half - round gutter machines that are designed to enhance production precision and efficiency. These machines are made of high - quality materials for durability and longevity, allowing users to craft beautiful and functional gutters for their projects.

Box gutters are known for their large capacity and are often used in commercial buildings or in areas with high rainfall. Box gutter machines can produce gutters in different sizes, ranging from 6" to 10". There are also combo box gutter machines available, such as the 6/7 Combo True Box Gutter Machine, 7/8 Combo True Box Gutter Machine, and 8/9 Combo True Box Gutter Machine. These machines are engineered to meet the specific demands of commercial gutter production, providing strength and reliability.

Downspout machines are specifically designed to create the vertical pipes that carry rainwater from the gutters to the ground or a drainage system. They can produce downspouts in all sizes and profiles, including smooth, round, and corrugated. Sizes typically range from 2" through 6" for round downspouts. For example, there are machines available that can produce high - quality downspouts quickly and efficiently, ensuring a seamless connection to the gutter system.

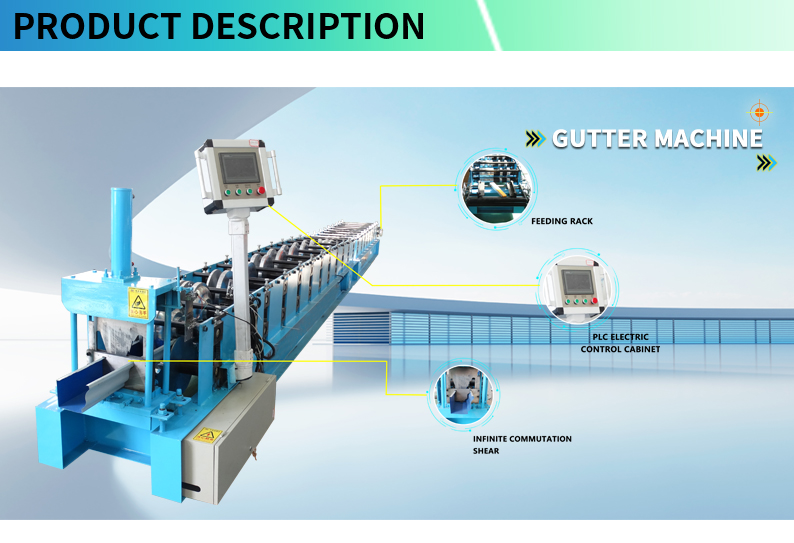

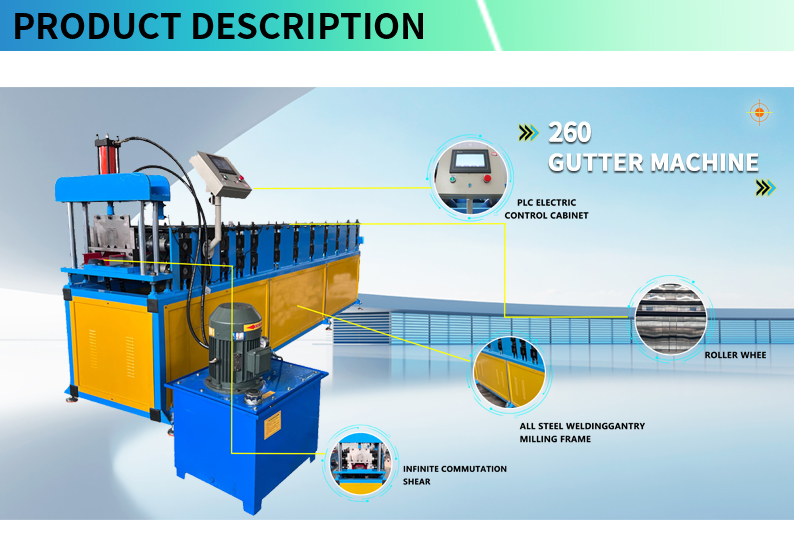

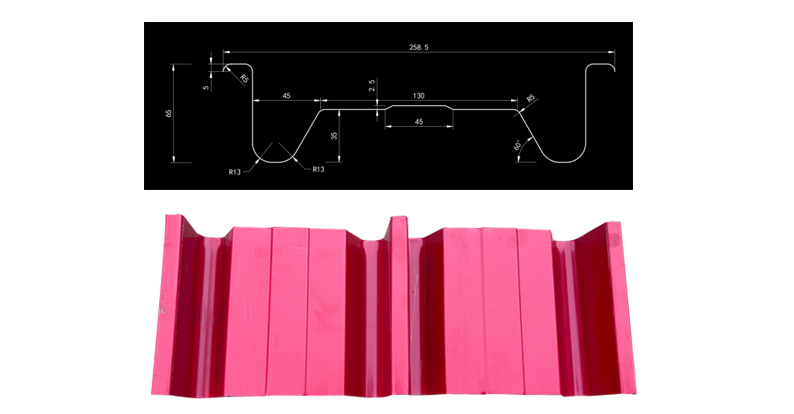

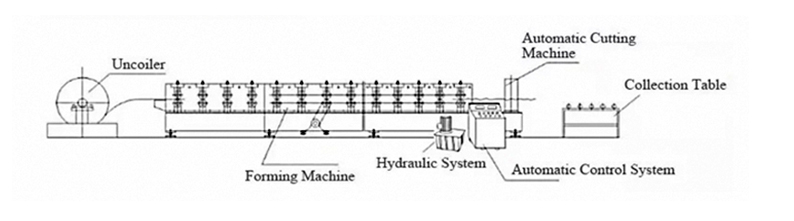

The working process of a gutter machine generally starts with the decoiling of the raw material coil. The coil, which can be made of aluminum, steel, or copper, is loaded onto a reel stand. Many modern gutter machines, like those from New Tech Machinery, have two 360° rotatable reel stands for easy coil loading. The material then goes through a feeding mechanism and enters the roll - forming section. In this section, a series of rollers gradually shape the flat material into the desired gutter profile. The rollers are precisely designed to create the specific shape, whether it's a K - style, half - round, or box gutter. After the roll - forming process, the gutter reaches the cutting section. Here, a shear mechanism, which can be manually powered with hardened tool - steel blades and shear dies, cuts the gutter to the required length. Finally, the finished gutter is discharged from the machine.

By producing gutters on - site with a gutter machine, contractors can save on transportation costs associated with pre - fabricated gutters. Additionally, the ability to quickly produce gutters at a rate of about 50 feet per minute means that the gutter for an entire average - sized house can be completed in under an hour. This saves valuable labor time, which in turn reduces overall project costs. For example, if a contractor were to purchase pre - fabricated gutters and transport them to the job site, they would need to factor in the cost of shipping, handling, and potential damage during transit. With a gutter machine, these costs are eliminated, and the machine can pay for itself relatively quickly through these savings.

Gutter machines allow for a high degree of customization. Contractors can produce gutters in the exact lengths and widths required for a particular project. This is especially important in complex or unique architectural designs where standard pre - fabricated gutters may not fit. For instance, in a historic building with irregular rooflines, a gutter machine can be used to create gutters that conform precisely to the shape and dimensions of the roof, ensuring proper water drainage. Different materials can also be used with the same machine, allowing for customization based on the client's aesthetic and durability preferences.

When gutters are produced on - site using a gutter machine, there is better control over the quality of the product. The process of roll - forming and cutting is precise, resulting in gutters with consistent dimensions and smooth finishes. This reduces the likelihood of leaks or other issues that can occur with poorly - made gutters. For example, in a seamless gutter production using a machine, there are no joints or seams (unlike traditional pre - cut and assembled gutters), which are common sources of leaks. The use of high - quality materials in the gutter - making process, along with the precision of the machine, ensures that the gutters will have a long lifespan and perform effectively in diverting rainwater away from the building.

In residential construction, gutter machines are used to install gutters on new homes. K - style gutter machines are particularly popular in this sector due to the widespread use of K - style gutters in residential architecture. Contractors can quickly produce and install gutters, protecting the home's foundation, doors, windows, and landscaping from the harmful effects of stormwater. In areas that receive significant rainfall, such as regions with an average annual rainfall of over 35 inches, properly installed gutters made with a gutter machine are essential for maintaining the integrity of the home.

Commercial buildings often require larger - capacity gutters, such as box gutters. Box gutter machines are used in commercial construction projects to produce gutters that can handle the large volume of rainwater runoff from extensive rooftops. These gutters are crucial for protecting the building's structure, as well as for preventing water damage to the interior of the building and any stored goods. In addition, downspout machines are used to create the necessary downspouts for commercial gutter systems, ensuring efficient water drainage.

For renovation and restoration projects, gutter machines offer the advantage of being able to match the existing gutter style or create custom gutters that blend in with the historical or unique design of the building. In historical restoration projects, half - round gutter machines may be used to replicate the original gutter style, maintaining the authenticity of the building. In renovation projects where the homeowner wants to upgrade the gutter system, a gutter machine can be used to produce new gutters that are more efficient and durable, while still complementing the overall look of the house.

Gutter Machine is an automated system designed to clean and maintain the city's drainage systems. It is a sophisticated piece of equipment that can be deployed in various environments, from bustling city streets to quiet suburban neighborhoods. The machine's primary function is to clear debris and waste from gutters, preventing blockages that can lead to flooding and water damage.

One of the most impressive features of the Gutter Machine is its autonomous operation. Equipped with advanced sensors and AI algorithms, the machine can navigate through complex drainage networks without human intervention. This capability significantly reduces the need for manual labor, making waste management more efficient and cost-effective.

The Gutter Machine is also equipped with a powerful suction system that can remove a wide range of materials, from leaves and paper to heavier debris such as plastic bottles and small branches. The collected waste is then sorted and compacted within the machine, reducing its volume and making it easier to transport and recycle.

Another key benefit of the Gutter Machine is its ability to operate in all weather conditions. Whether it's a light drizzle or a heavy downpour, the machine can continue its work uninterrupted. This ensures that the city's drainage systems remain clear and functional, even during adverse weather events.

The environmental impact of the Gutter Machine is also noteworthy. By preventing blockages and reducing the risk of flooding, the machine helps to protect local ecosystems and waterways. Additionally, the sorted waste can be recycled, further reducing the overall environmental footprint of urban areas.

In terms of maintenance, the Gutter Machine is designed to be durable and long-lasting. Its robust construction can withstand the rigors of daily operation, and its modular design allows for easy repairs and upgrades. This ensures that the machine remains a reliable tool for waste management for years to come.

The Gutter Machine is not just a piece of equipment; it represents a shift towards smarter, more sustainable urban living. As cities continue to grow and face increasing environmental challenges, the Gutter Machine offers a practical solution to one of the most pressing issues: waste management.

In conclusion, the Gutter Machine is a game-changer in the field of urban infrastructure. Its innovative design, autonomous operation, and environmental benefits make it an invaluable asset for any city. As we look towards a future where sustainability and efficiency are paramount, the Gutter Machine is leading the way in creating cleaner, safer, and more resilient urban environments.