A Floor Deck Roll Forming Machine is a specialized piece of equipment that plays a pivotal role in the construction industry, primarily used for manufacturing high - quality steel floor decks. These machines are designed to transform flat sheets of steel into precisely shaped floor deck profiles through a continuous bending process known as roll forming.

Floor Deck Roll Forming Machine:

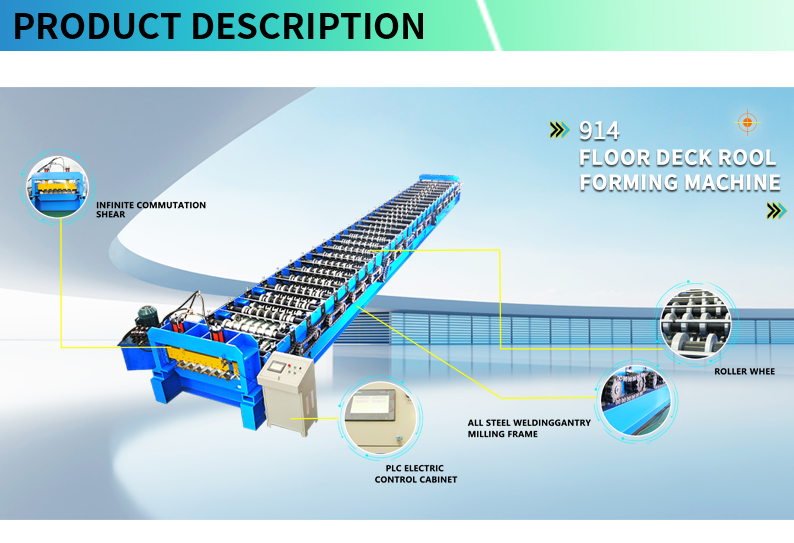

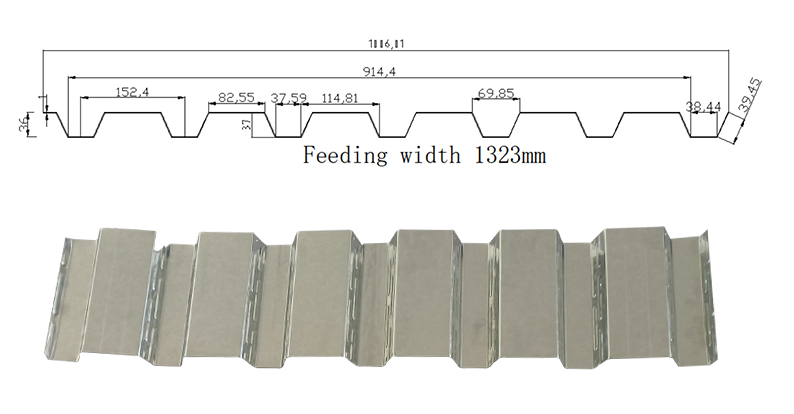

The roll forming process begins with a flat steel coil being fed into the machine. As the steel passes through a series of precisely engineered rollers, it is gradually bent and shaped into the desired floor deck profile. This sequential forming method ensures consistent and accurate shapes, meeting strict industry standards for strength and dimensional accuracy. The entire process is highly automated, often controlled by a programmable logic controller (PLC) system. This allows operators to easily adjust parameters such as speed, profile shape, and length, enabling the production of various floor deck types, including trapezoidal, cellular, and composite floor decks.

One of the key advantages of a Floor Deck Roll Forming Machine is its high - speed and high - volume production capabilities. Compared to traditional manufacturing methods, roll forming can produce floor decks at a significantly faster rate, reducing production time and increasing overall productivity. Moreover, the automated nature of the machine minimizes human error, resulting in products with consistent quality. This consistency is crucial for construction projects, as it ensures that floor decks fit together seamlessly, enhancing the structural integrity of buildings.

In terms of material efficiency, Floor Deck Roll Forming Machines are highly efficient. The continuous roll forming process generates minimal waste, as the steel is precisely shaped without the need for excessive cutting or trimming. This not only reduces material costs but also contributes to a more sustainable manufacturing process. Additionally, the machines can work with a variety of steel grades, allowing for the production of floor decks with different strength and durability requirements, suitable for various construction applications, from commercial high - rises to industrial warehouses.

Another significant benefit is the versatility of Floor Deck Roll Forming Machines. They can be customized to produce floor decks of different widths, depths, and lengths, as well as with various surface finishes and hole patterns. This customization ability makes them adaptable to a wide range of construction designs and specifications. For example, in some projects, floor decks may need to be pre - punched for electrical conduits or mechanical penetrations, and the roll forming machine can be configured to meet these specific requirements.

Floor Deck Roll Forming Machines are also designed with operator safety in mind. They are equipped with various safety features, such as emergency stop buttons, safety guards, and interlocking systems, to prevent accidents during operation. Regular maintenance of these machines is relatively straightforward, with most modern models featuring modular components that can be easily replaced or serviced, reducing downtime and ensuring continuous production.

In conclusion, Floor Deck Roll Forming Machines are essential in the modern construction industry. Their ability to produce high - quality, customized floor decks efficiently, with minimal waste and high safety standards, makes them an indispensable asset for construction material manufacturers and construction companies alike. As the construction industry continues to evolve, the demand for these advanced roll forming machines is expected to grow, driven by the need for faster, more sustainable, and more flexible construction solutions.

In the dynamic realm of construction technology, the Floor Deck Roll Forming Machine has become a pivotal innovation, dramatically boosting the efficiency and output of building projects. This cutting-edge equipment is engineered to manufacture floor decking panels, which are critical elements in the construction of multi-story buildings, warehouses, and other structures necessitating robust and resilient flooring systems.

The Floor Deck Roll Forming Machine functions by processing metal coils, usually steel, through a sequence of rollers that mold the material into the required profile. This process is continuous and highly automated, enabling the swift production of floor decking panels that are uniform in quality and dimensions. This not only accelerates construction schedules but also minimizes material wastage, making it an eco-friendly option.

A major advantage of the Floor Deck Roll Forming Machine is its adaptability. These machines can produce a diverse array of panel profiles, each tailored to specific structural needs. Whether it's a shallow or deep decking profile, the machine can be configured accordingly. This adaptability allows contractors to standardize their material procurement, simplifying the process of obtaining different flooring components

.

Furthermore, the Floor Deck Roll Forming Machine delivers exceptional precision and uniformity. The automated nature of the process guarantees that each panel is identical to the previous one, which is essential for the building's structural integrity. The machine's accuracy also means that minimal on-site manual adjustments are needed, streamlining the construction process and reducing the likelihood of human error.

Another notable benefit is the reduction in labor expenses. Traditional methods of floor decking construction involve extensive manual labor, which is both time-intensive and prone to inconsistencies. The automated production of floor decking panels using a roll forming machine means fewer workers are required on-site for this aspect of construction, leading to significant cost savings.

The Floor Deck Roll Forming Machine is also designed for ease of use. Contemporary machines are equipped with user-friendly control panels and PLC systems that allow operators to easily program and adjust machine settings. This reduces the learning curve for new operators and ensures that the machine can operate efficiently with minimal oversight.

In addition to its practical benefits, the Floor Deck Roll Forming Machine offers aesthetic enhancements. The panels produced by these machines can be designed with various surface patterns, which can improve the visual appeal of the finished floor. This is particularly important in commercial and retail spaces where the floor's appearance can contribute to the overall atmosphere of the environment.

In summary, the Floor Deck Roll Forming Machine is an indispensable tool in the modern construction industry. It provides a blend of efficiency, adaptability, precision, and cost-effectiveness that traditional construction methods struggle to match. As the demand for quicker, stronger, and more sustainable building solutions continues to rise, the Floor Deck Roll Forming Machine stands out as a key factor in shaping the future of construction.