Sandwich panel machines are the cornerstone of modern insulated building material manufacturing.At their core, a sandwich panel making machine is a specialized piece of equipment designed to continuously produce sandwich panels.This machine precisely forms the metal facings (typically steel or aluminum) and simultaneously injects, applies, or foams the core insulating material (like PIR, PUR, EPS, mineral wool, or rockwool) between them, bonding the layers under controlled pressure and temperatu

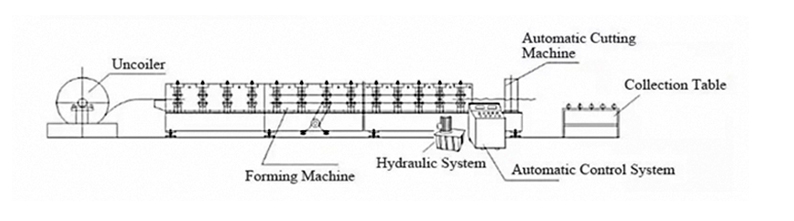

Sandwich panel machines are the cornerstone of modern insulated building material manufacturing.At their core, a sandwich panel making machine is a specialized piece of equipment designed to continuously produce sandwich panels.This machine precisely forms the metal facings (typically steel or aluminum) and simultaneously injects, applies, or foams the core insulating material (like PIR, PUR, EPS, mineral wool, or rockwool) between them, bonding the layers under controlled pressure and temperature to create a rigid, composite panel. For high-volume, efficient production, these individual sandwich panel making machines are integrated into a complete sandwich panel machine production line. This automated line typically includes material decoilers, cleaning and pretreatment units, roll forming stations for the top and bottom metal sheets, the core material handling and application system (central to the sandwich panel making machine itself), a double belt laminating press for curing and bonding, a cutting station (flying cut-off saw), stacking systems, and sometimes panel profiling or shaping units. The entire sandwich panel machine production line streamlines the process from raw coil metal and core material to finished, packaged panels ready for shipment. Whether referring to the singular sandwich panel making machine performing the core bonding function or the comprehensive sandwich panel machine production line automating the entire manufacturing sequence, this technology is vital for producing the energy-efficient wall and roof panels essential for modern construction, cold storage facilities, and industrial buildings. Investing in the right sandwich panel machine or full production line is crucial for manufacturers aiming for quality, efficiency, and scalability.